A COMPARATIVE TRIAL OF THE POLLEN SUBS 2020

Part 1

Beekeeper-Funded Research

First published in ABJ July 2021

Randy Oliver

ScientificBeekeeping.com

California has been in a “mega-drought” for a decade. In many areas, there is not enough natural forage in late summer for building colonies back up to cluster sizes large enough to supply strong hives for almond pollination in February. For many years I moved my bees out of state to better summer/fall pasture, but then learned that I could instead build them up near home by providing pollen sub.

My sons and I now purchase a goodly amount of pollen sub each season, so we have considerable self interest in objectively comparing the relative performance of the products on the market. I ran a comparative trial of subs back in 2013 [[1]]. Since then, since I’m continually asked about pollen subs by beekeepers worldwide. That, plus the fact that there are two new products on the U.S. market, had gotten me teetering on the edge of running another field trial (they’re a LOT of work). And then a group of commercial beekeepers from near Bakersfield, California, who wanted to test their “homebrew” formulation against others on the market, kicked in some funding toward me performing a follow-up trial.

Practical application: In the increasingly-arid West, the main income source for many beekeepers is from renting hives for almond pollination. Due to our lack of natural nectar and pollen flows in late summer, many of us depend upon providing our bees with “artificial diets” to stimulate the rearing of the brood that will form the winter cluster. This experiment is essentially a “progress report” on the state of development of such artificial diets.

Experimental Design

I ran this experiment as a “Consumer Reports” type of unbiased comparative trial of what’s on the market. I asked each manufacturer to provide a fresh batch of their “top of the line” product.

Disclaimer: Although the manufacturers generously provided the pollen subs, I received no compensation or other influence from any manufacturer. Our out-of-pocket costs, labor, and lost income due to the poor performers came to over $20,000, which was funded solely by donations from beekeepers to Scientific Beekeeping.

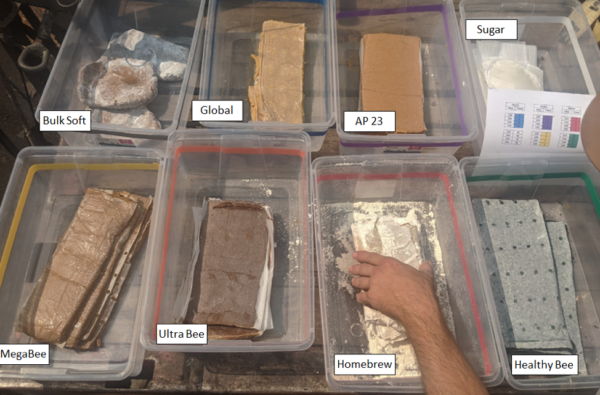

The subs came preformed in roughly 1-pound patties sandwiched between waxed paper sheets (Table 1), with the exception of Mann Lake’s Bulk Soft, which we cut into 1-pound chunks for each feeding. I mixed and rolled out the Sugar Controls myself, consisting of hand-kneaded Drivert sugar mixed with Dadant or ProSweet bulk syrup into a patty, weighed to provide a half pound of sugar (since most of the subs were around 50% sugar). I assigned a color code to each patty type (Table 1), in order to keep them all straight during feeding and analysis (Figure 1).

Fig. 1 A view of the tested patties, each type in a color-coded tub for field distribution. Two of the subs contained natural pollen (Global 15% and Homebrew), and thus should be considered as “pollen extender” patties, as opposed to being “pollen substitutes” (artificial diets).

Practical application: Using bee-collected pollen in a diet confers the risk of transmitting pathogens. I’ve long wondered whether there was a connection between the widespread practice of (illegally) feeding bee-collected pollen from China (which could contain pathogens from two species of honey bee, as well as other pollinators), and the rapid spread of Nosema ceranae and viruses prior to the CCD epidemic in the early 2000s. Trapped pollen can transmit AFB, chalkbrood, and nosema spores as well as viruses, so be careful of its source. I checked with Global, and the pollen they use is irradiated by IOTRON before coming to their warehouse.

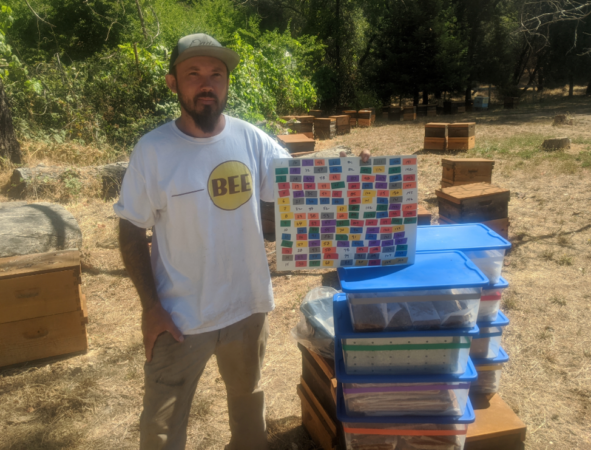

As you might imagine, feeding 144 randomly-assigned hives the proper patty at each feeding required careful handling and distribution of the patties. We couldn’t really “blind” ourselves as to treatment when we were applying the patties or grading, since some of the patties had distinctive looks. So we put a piece of colored tape on the number tag of each hive (Figure 2), and did our best to not pay attention to patty type, although it soon became clear that some “colors” were consistently outperforming others.

Fig. 2 First feeding: Eric showing the color-coded patty delivery tubs and hive color-code tapes (before placing them on the hive number tags), in order to ensure that every hive got the correct patty type at each feeding.

For every feeding, we carefully first separated each sub type into the color-coded tubs, and then laid the patties out by type on tops of the hives in each yard, and finally double-checked for proper distribution prior to placing the patties into the hives.

Practical observation: The subs varied widely in texture and moisture content. (I strongly suggest to the manufacturers that they make their patties moist, and to wrap each boxful in a plastic bag, so that the patties don’t dry out during storage.)

Choice of Trial Yard Locations

In our California operation, we normally build up established hives up for winter by feeding them pollen sub (and sometimes sugar syrup) during September and October. For this and other tests of pollen subs, I intentionally place the hives in yards which, from previous experience, we know that colonies not given supplemental feeding will go downhill in strength.

We ran three replicates of this trial in different yards, in order to test the subs under various conditions of elevation and vegetation type. Yards E and T were at ~1600 ft), my home yard (H) at 2850 ft; each yard was surrounded by scarce, but differing floral resources.

Experimental history: We ran a pollen sub trial in 2018 in Yard E, in which we were able to successfully nearly double colony strength by feeding from early August through early November [[2]], and assumed that we’d be able to do the same in 2020 (Figure 3).

Fig. 3 Yard E is typically a disaster for colonies after mid-July. Because it had worked well for a similar trial in 2018, we intentionally stocked it heavily with 72 hives to ensure competition for any natural pollen.

Grading for Strength and Analysis

We used California-style cluster grading (number of frame interspaces full of adult bees — “FOB”), done on a cold day or at dawn following a cool night, before the clusters have broken (we can consistently grade to quarter-frame consistency). Instead of trying to equalize all 144 test hives for strength, we started the trial with singles from late nucs, ranging from 5-12-frame strength (median 7.5 FOB). I did this intentionally, in order to see whether starting strength made a difference.

Note that the hives were not physically placed in actual groups, but were scattered throughout each yard. For a randomized block design, we recorded the initial grades for strength in each yard, sorted them from strongest to weakest, and then randomly assigned the eight pollen sub types first to the strongest eight hives in that yard — no matter where they were in the yard — and then to the next strongest eight hives, and so forth down the line. Thus, each patty type was fed to hives over the full range of starting strengths.

We graded for starting strengths on 10 August. Unfortunately, nighttime temperatures did not drop low enough for tight cluster formation, so we did our best. Since cluster grading is designed to be a comparative grade (rather than an absolute estimation of the number of bees), we graded consistently, and so we felt that the gradings were accurate enough, relative to the other hives in each yard, for comparison at that time point.

Conversely, the midpoint November grading took place during a sudden cold snap, and the bees were packed as closely as they could get; median cluster size had shrunk considerably. The February endpoint grading was performed on a cool day when the clusters were moderately tight.

Practical application: Despite the effect of temperature on cluster size, for the best-performing pollen sub group, cluster size shrunk only slightly between the hot August (median 7.75 FOB) and cold November gradings (median 6.5 FOB), and had grown larger than starting strength by February (median 8.4 FOB).

Again, since the measurements at any time point were taken at the same time and under the same conditions in each yard, they would reflect the relative strengths of the colonies in that yard at that time. I’m comfortable with the FOB grading data as collected.

Timeline

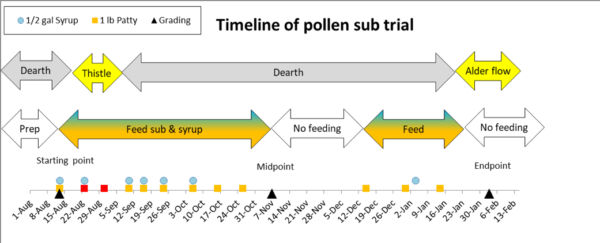

The trial ran from 10 August, 2020 through 1 February 2021, taking a brief break from feeding when the bees ceased consuming the patties when cold weather hit in November (Figure 4).

Fig. 4 The above chart shows the timings of feedings and gradings, as well as the occurrence of two natural pollen flows (the thistle flow occurred in only two of the yards; yard H received 2 feedings [red] during that time). We performed final grading prior to the emergence of any bees from the alder flow.

We prepared the hives as singles during July, added second brood chambers containing eight drawn combs and two combs of foundation (in order to give the bees room to store stimulatory sugar syrup without crowding out the brood nests) shortly before the first grading for strength on August 10, and began feeding the pollen subs and syrup on August 15, continuing through October 29, prior to midpoint grading on November 9 and 10. We were surprised by a nectar and pollen flow in yards E & H in mid-August, so skipped feeding those yards during that time. We ceased feeding after midpoint grading, and resumed feeding on 15 December. The final grading was performed three weeks after the start of a natural pollen flow from alder trees, before any bees that could have been reared on alder pollen emerged.

Nutritional Physiology Measures and Gut Microbiome Analyses

In order to see whether the feeding of different pollen subs affected the gut microbiota, vitellogenin levels, or body weights of the bees, we also took samples of worker bees from a pollen comb at the start and midpoints, froze them on dry ice, and shipped them to my collaborator, Dr. Vincent Ricigliano at USDA for molecular analysis.

Feeding of Pollen Subs and Sugar Syrup

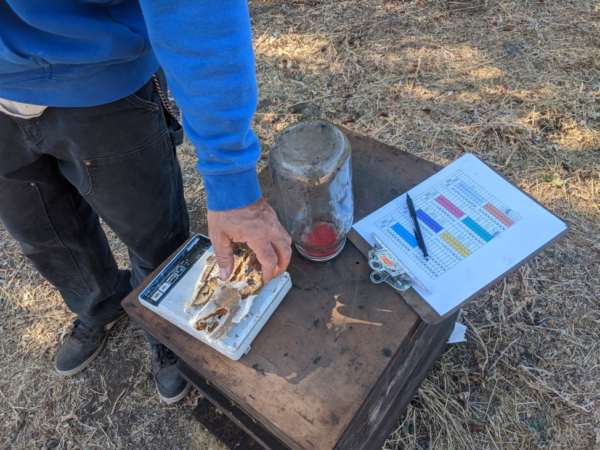

We monitored consumption of sub for each yard, and as soon as the most-attractive subs were nearly consumed, we would give the yard another round of feeding. Thus, the feeding of pollen sub was essentially ad libitum, with unconsumed patty remainders being removed and weighed (Figure 5). We generally fed a half gallon of light syrup at each feeding of pollen sub, along with some intermediate feedings, but refrained from feeding syrup when the clusters were still surrounded by ripening syrup from the previous feeding. By November, all colonies had largely filled the second chamber with sugar “honey.”

Fig. 5 At each feeding, we removed and weighed any sub that had not been consumed.

Overall, between mid-August and the end of October we fed every hive seven 1-lb. patties (nine in Yard H, plus 13 half gallons of light syrup (diluted ProSweet or Dadant).

Details and Observations

At the first feeding, the bees eagerly consumed all the subs. Not surprisingly, the most rapidly consumed patties were the two containing natural pollen. The only sub for which we saw bees kicking out unconsumed portion was the Healthy Bee (I suspect due to its thyme oil content), which we consistently observed in front of the hives (Figure 6).

Fig. 6 Unconsumed green Healthy Bee patty debris in front of a hive. This was the only patty type for which we consistently saw removal.

In mid-August, once daytime highs exceeded 95°F, there was an unexpected nectar and pollen flow from Yellow Star Thistle in the E and T yards (I will expand on this in another article). In response, the colonies packed a couple of combs with beebread, and seriously ramped up broodrearing. Since I’ve previously found that there is no benefit to feeding pollen sub when there is a flow of natural pollen going on [[3]], we skipped two feedings of pollen sub at those two yards, until the colonies had consumed most of the natural pollen, and had cut back again on broodrearing.

There were also at least two tiny surprise swarms in Yard E (Figure 7).

Fig. 7 We also found a couple of small swarms in Yard E, but were unable to determine which colony or colonies they had come from. At any feeding, whenever I suspected that a colony had an issue, I’d check to confirm queen rightness and good larval survival.

This was also the first year that we regularly saw Small Hive Beetle larvae on pollen patties. We removed any infested patty parts, weighing them before disposing of them (Figure 8).

Fig. 8 There were only minor issues with Small Hive Beetle larvae, and we seldom observed them on the thyme-scented Healthy Bee patties. Note how the portion of this patty outside of the cluster has dried, which was typical for those which were not rapidly consumed (we made a point to place all patties within the cluster as best possible).

The Refusal of Colonies to Grow

Contrary to our experience in previous years in the same yards, during which fed colonies increased in strength [[4]], we were frustrated by the number of colonies that didn’t grow, despite having very low mite counts and consuming a goodly amount of their patties at every feeding. This went on week after week during September and October. A number of colonies cut back on their consumption of pollen sub, and we could often see a small number of cells filled with incoming natural pollen throughout the trial. The colonies continued to gain plenty of weight from the fed sugar syrup, but simply refused to grow in strength. I will discuss this frustrating turnout in another article.

At each feeding, whenever I saw a colony that was unusually week, I pulled frames from the brood nest to confirm that it was queenright, exhibiting good larval survival, and free from brood disease. I also regularly spot-sampled to confirm that varroa was not an issue. I took photos in mid-October of the brood in one very weak colony (approximately a 3-frame cluster) that was consuming its pollen sub well (Figure 9).

Fig. 9 A brood comb from a very weak hive on October 15. Note the solid brood pattern, indicating good survivorship of the larvae. Yet despite rearing healthy brood, these weak colonies simply refused to grow.

Was the poor colony growth due to the high temperatures? The temperature on the day (October 15) of the photo in Figure 9 reached 95°F — 15 degrees hotter than on the same day in 2018 (when colonies grew well in the same yard). The colonies were anything but hungry — they were being continuously fed pollen sub, and many stored so much sugar syrup “honey” in their upper brood chambers that I checked every hive to ensure that every queen had access to a frame of empty dark drawn comb above the cluster in which to lay eggs, exchanging frames if necessary (Figure 10), and held off on syrup feeding for several days afterwards so that they wouldn’t fill them with syrup and prevent the queen from utilizing them. To my surprise, in no case did I observe a colony utilizing that comb to expand the brood nest.

Fig. 10 I placed a drawn comb centered above the brood of every hive to provide open cells for brood nest expansion upwards. Unfortunately, none of the colonies took advantage of them.

Practical application: During the hot, dry weather many colonies appeared to go into “survival mode” (as opposed to “buildup mode”), storing fed syrup and cutting back on their consumption of the pollen subs. Even colonies that consumed every bit of their continually-fed subs barely held their strength. I spoke with several other professional beekeepers in hot climates, who often observe the same — that colonies cease growing until the weather cools or a nectar flow begins. But as I will discuss in another article, it’s not clear that temperature alone is the issue.

Midpoint Grading and Winter Break

We stopped feeding shortly before midpoint grading on 9 November, since the colonies were winding down broodrearing as the weather cooled. After grading, we swapped frames of honey to roughly equalize the amount of honey above the clusters for all hives.

Resumption of Feeding

We resumed feeding pollen sub on 15 December, and gave each hive a half gallon of light syrup on 5 January for stimulation. During this final feeding period, due to there being a wide range of cluster sizes, we fed each colony as much patty as it would consume (so as not to hold back the stronger colonies) — up to 4 lbs. per hive — and didn’t remove any unconsumed patty.

Since I suspected that the high concentration of thyme oil in the Healthy Bee patties was causing problems, after consultation with the manufacturer, he supplied me with a batch of thyme-oil-free patties, which we used at the resumption of feeding (Figure 11).

Fig. 11 A photo at final grading of one of the better Healthy Bee hives. It had been consuming a version of Healthy Bee without essential oils starting in December. But there had been some alder pollen coming in, so I can’t say that this nice pattern was entirely from the thyme-oil-free Healthy Bee.

We ceased feeding additional pollen sub once our expected natural flow of alder pollen began in January. The grand total of patty consumption over the entire course of the trial ranged from 9-13 lbs. per colony.

As February approached, there was a goodly amount of sealed brood in the hives, and the colonies would soon be rapidly increasing in strength for almond pollination. In my 2013 trial, we learned that once alder pollen started coming in, all colonies grew equally. So we performed final grading 20 days after the beginning of the alder pollen flow, prior to when any brood that could have been fed by nurses consuming alder pollen could emerge. We graded on the cool morning of 1 February (Figure 12).

Fig. 12 During grading, I stepped back to snap a photo of Eric, Ian, and Alice Dunbar recording the number of filled frame interspaces in an upper box.

Results

Despite the disappointing growth of some of the test colonies in response to ad-libitum feeding of artificial diets (compared to the amount of growth in previous years), by the time we were ready to take the colonies to almonds, there was nonetheless a very clear benefit from feeding pollen sub, with a return of around $5 value in rentable frames of bees for almond pollination for every dollar invested in pollen sub (compared to the Control colonies fed sugar alone).

Coming Next

I’m out of space, but will present a detailed breakdown of the results of this trial in subsequent installments. A teaser: Some of the results were surprising to us, and sometime conflicting. As far as the resulting numbers of frames of bees for rental in the almonds, some subs clearly outperformed the others. But even more exciting, it appears that we could have predicted their performance, relative to each other, based solely upon an analysis of their amino acid contents. This finding may allow all beekeepers and manufacturers to improve the formulations of their pollen subs, and I’ve created a handy calculator to allow them to do so.

Acknowledgements

I wish to thank the manufacturers who donated fresh batches of their products, beekeeper Peter Borst, who assisted me greatly in library research, and Dr. Vincent Ricigliano, who will coauthor the next installment. This research was funded by donations by beekeepers, which allow me to perform these expensive field trials. Thank you for your support!

References

[1] http://scientificbeekeeping.com/a-comparative-test-of-the-pollen-sub/

[2] http://scientificbeekeeping.com/an-experiment-to-improve-pollen-sub-part-2/

[3] http://scientificbeekeeping.com/when-to-feed-pollen-sub/

[4] http://scientificbeekeeping.com/an-experiment-to-improve-pollen-sub-part-2/